NEW GENERATION AUTOMOTIVE ELECTRONIC, ELECTRIC TRAINNING COURSE (Standard course) |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A. WHO IS THIS TRAINING COURSE FOR? | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

1. Automotive electric repairers who want to learn advanced professional 2. Automotive mechanical repairers who want to learn more about electronic 3. Students studied electrical and electronic technical 4. Civil electronic repairers who want to do automotive electronic job 5. Technical consulting staff who want to add new knowledge 6. Teachers teach automotive electric who want to learn advanced 7. Workshop management who want to have knowledge about new technologies and equipments investment 8. Companies, businesses, military units, vocational training schools want to enhance corporate training |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| B. TIME | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

40 days (All day, not include Saturday and Sunday) |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| C. LOCATION | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Floor 3, Building A25, Institute of Physics, Vietnam Institute of Science and Technology No.18 Hoang Quoc Viet, Hanoi, Vietnam.

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| D. QUANTITY | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

10 persons/course |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| E. LECTURER | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

1. Master Duong Tuan Dung 2. Master Bui Minh Hang 3. Engineer Tran Viet Phu |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| F. STUDY TOOLS | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

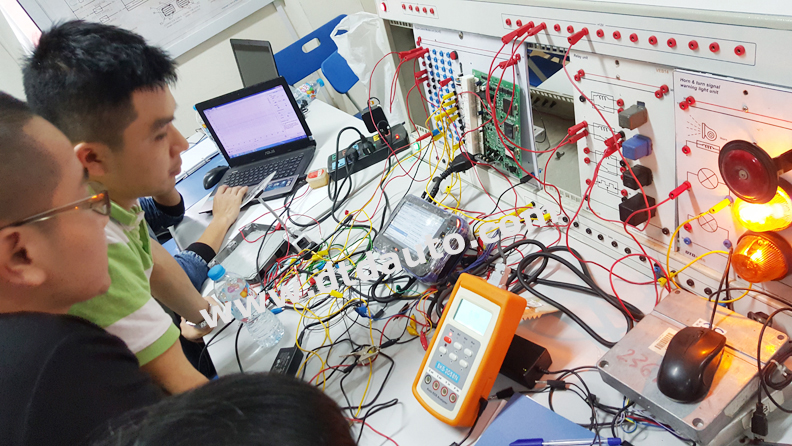

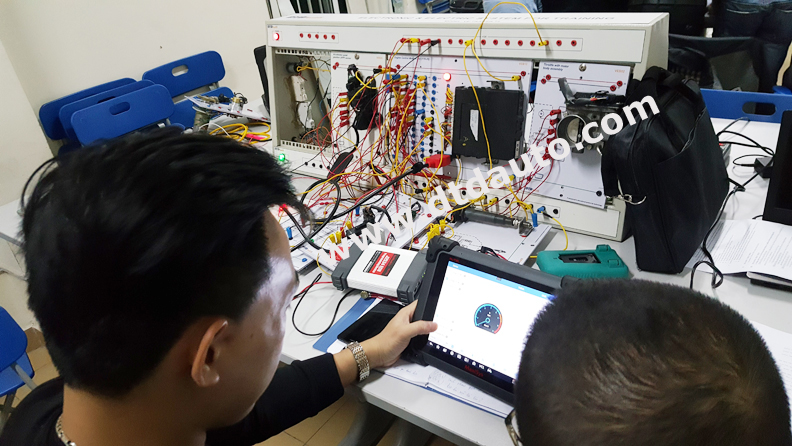

- Simulator equipments for training - Computer, Internet, software look up repairing and training - Measuring & checking equipment, scanner and document - Practice at workshop - Laptop (student ownequipt) |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| G. OPENNING | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Contact us for more details through: +84.43.7845426 |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| H. TUITION FEES | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Contact us for more details through: +84.43.7845426 |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| I. TRAINING COURSE CONTENT | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

DTDAuto have been compiled the program and content are equivalent automotive electronic & electric engineer level of developed countries in the world.

I. ELETRONICAL ENGINERING & ELECTRONIC IN STRUCTURE, OPERATING AND REPAIRS OF AUTOMOBILES 1. Electrical engineering, electronic in structure, operation and of generation cars 2. Major technical English in automobile repairs 3. Computer & internet applied in automobile repairs 4. Looking up, analyze operation principle; diagnose faults by electrical wiring diagram: functional block diagram, principle diagram, assembling diagram and technical parameters. 5. Looking up, analyze live data and diagnose position of malfunction by methods: 6. Fault diagnosis and repair techniques applied for automatic control systems on cars (including independent electromagnetic control, electronic and electronic control unit (ECU)). 7. Measure electric technical parameters, electric signals and diagnose fault by direct measuring tools, computer and diagnostic scanner. II. ELECTRIC & ELECTRICAL TECHNOLOGIES FOR POWERTRAIN SYSTEM (PCM) 1. Electric starting system, charging system and power supply system 2. Electronic & electromagnetic ignition systems (on TOYOTA) 3. Electronic fuel injection system (on TOYOTA) 4. Common Rail diesel injection system for CP1, CP3, Delphi on HUYNDAI. Programming and set QR code for electronic injectors. 5. Engine auxiliary systems: III. ELECTRIC & ELECTRICAL TECHNOLOGIES FOR THE CHASSIC SYSTEM 1. Anti-lock braking system (ABS) and brake assist system (BA) 2. Traction control system (TRAC/A-TRAC/TCS) 3. Crawl control system and downhill assist control (DAC) 4. Electronic stability control systems as ESP, VSC, EBD 5. Electronic air suspension system (EAS) 6. Electric power steering system (EPS/MDPS), programming and reset steering angle when adjust, replace sensor and ECU. IV. ELECTRIC & ELECTRICAL TECHNOLOGIES FOR THE BODY & IMMOBILIZER SYSTEM 1. Signal lighting system 2. Instrument panel system (IP), programming, repair and adjustment value of digital odometers. 3. Wiper & washer system, door locking system and power window system. 4. Airbag system (SRS), programming, repair and reset airbag ECU. 5. Immobilizer system, electronic key programming, repairing immobilizer system. V. TECHNICAL, SKILL AND REPAIR METHOD 1. Repair common faults of electronic control system (ECU/ ECM/ PCM/ ABS, SRS) 2. Skill to analyze live data for diagnosing, adjustment and repair complex faults by intelligent diagnostic equipment (diagnostic scanner) 3. Skill to adjust idle speed, air/fuel ratio and engine power of electronic fuel injection system (EFI). 4. Skill to use and operate specialized equipment for washing, cleaning and checking electronic injector quality (Injector Cleaner) 5. Thinking, knowledge development the way of professional repair techniques, help students develop self-study habits in the next year. 6. Practice at workshops in Hanoi city 7. Test, summaries, rate and certification |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| J. REGISTRATION DOSIER | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

1. Resume (send via email) 2. Application form 3. 03 images (size 3x4) 4. Other certification 5. Deposit fee 100 USD (to facilitate for training course management and organization) |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| K. RIGHT & POLICY | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

1. Support free technical documentation 2. Award the final course, free advanced course for excellent student 3. Provide certification training for students 4. Employment support at workshop in Hanoi (for excellent students) 5. Become a remote collaborators of DTDAuto 6. Support discount for students when purchase DTDAuto’s equipments. 7. Female students are given 50% discount 8. Support finds housing for students 9. Participate in events and other activities of DTDAuto |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| L. RELATED INFORMATION | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Download content of course >> |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M. COURSE PICTURES | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||